Pharmaceutical Packaging Line

-

Coffee Stick Sachet Production Line

(1)Adjust the sachet length by servo motor, it is simple and convenient to operate (stepping distance can be optionally adjusted: 60~200mm).

Email Details

(2)Controlled by HMI, safe and stable system, easy and reliable operation.

(3)Photoelectric detection mark, servo motor follow mark, to ensure the integrity and accuracy of the printed pattern position.

(4)Print batch number and easy tear automatically, easy to install and operate.

(5)Film width can reach 1000mm and form 8~16 lanes.

(6)The lengthways sealing, across sealing, embossing and cutting mechanism are all installed on the front panel of the machine with sufficient rigidity to ensure the same packaging dosage of each sachet.

(7)Reasonable layout, small dimension and good appearance. -

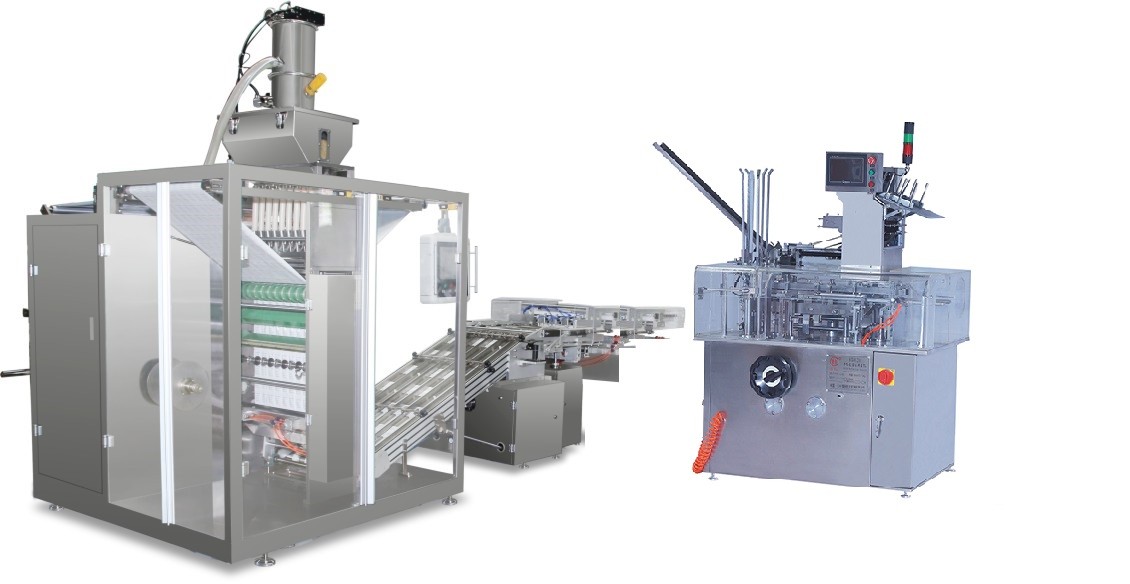

DXDK1200 and HDS120 paroduction line

(1)Sealing width can be max 600mm, so the machine can do 5 to 10 lanes.

Email Details

(2)The machine use one roll packing film which can be divided two parts for sealing, convenient adjustment.

(3)Lengthways sealing, across sealing, embossing, pertferation knife and finished sachet cutter all were controled by servo motor.

(4)Controlling system: with HMI control and buttone control, this is convinent for the operator to control the machine.

(5)If no packing material,machine will not absorb the carton and leaflet,pusher will stop working.

(6)Machine will stop automatically when ancillary stock in low level.

(7) Machine will stop automatically when there are leaflets but lack of box for three times.

(8)Machine will stop automatically when there are packaged product but lack of leaflets for three times. -

Hot

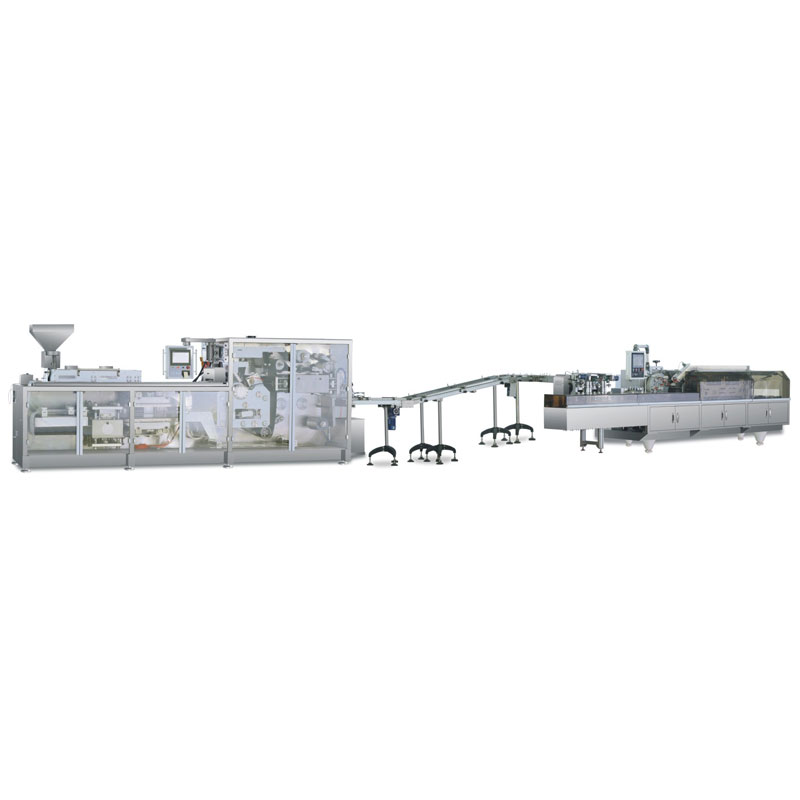

Sachet Production Line

(1)The sealing area can reach 450mm, form 5 to 9 sachets.

(2)The machine use one roll packing film which can be divided two parts for sealing, convenient adjustment.。

(3)The position of emboss,horizontal break and horizontal cutting can be adjusted and controlled by differential through HMI. (4)Reasonable layout,small volume and nice appearance.

(5)If no packing material,machine will not absorb the carton and leaflet,pusher will stop working.

(6)Machine will stop automatically when ancillary stock in low level.

(7) Machine will stop automatically when there are leaflets but lack of box for three times.

(8)Machine will stop automatically when there are packaged product but lack of leaflets for three times.Granule sachet packing production line Powder sachet packing production line liquid sachet packing production lineEmail Details -

Blister Packaging Production Line

(1)Space of forming,sealing,cutting system can be adjusted freely,suitable for different size plate

(2)Manipulator guiding,adjustable stroke,simple operation,reliability running

(3)Simplicity and convenience of replacing different molds.Changeable frequency

(4)It can be equipped cursor register,servo motor control stroke

(5)If no packing material,machine will not absorb the carton and leaflet,pusher will stop working.

(6)Machine will stop automatically when there are leaflets but lack of box for three times.

(7)Machine will stop automatically when there are packaged product but lack of leaflets for three times.

(8)Emergency stop switch is on electric cabinet,press this button to stop machine instantly when emergency.blister packing production line pharmacy blister packing production line food blister packing production lineEmail Details -

Liquid Filling Production Line

(1)Computer control, stepless speed regulating ,easy for operation

Email Details

(2)Capability abroad, wildly application, reliable quality

(3)Occupy small area, lower noise, salve the energy sources

(4)Good appearance, new frame, reasonable composition

(5)Changeable shape of bottle, just change the mold, and it is easy job.

(6)Can packing different product and also measure it

(7)PLC program control ,optoelectronic monitoring, stop automatically and display reasons when problem during the working process.

(8)Belt transmission,chain transmission,gear transmission,cam transmission, four bar linkage mechanism and electric and gas control mechanism. -

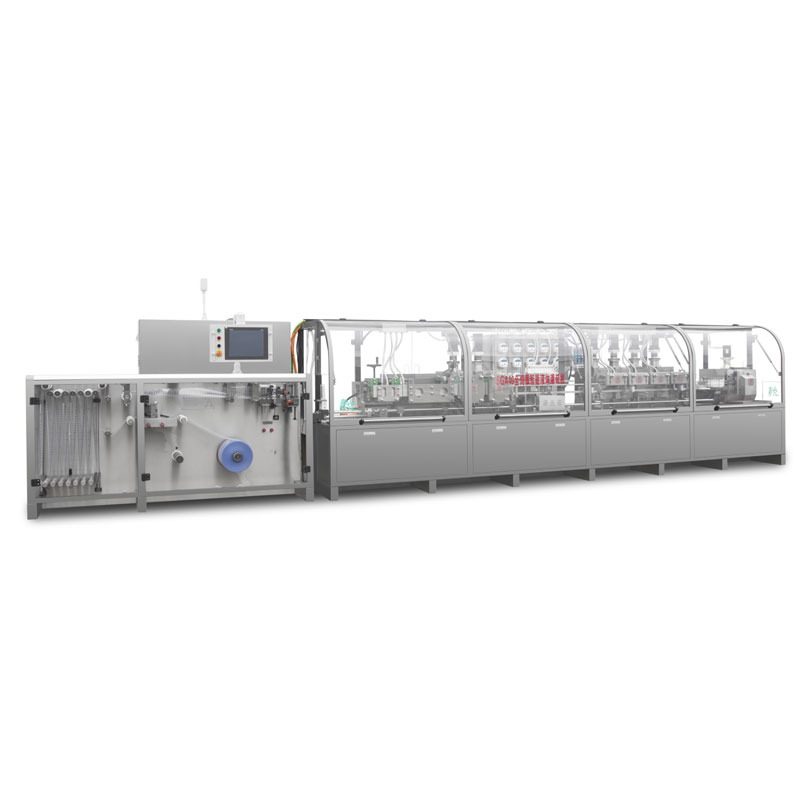

High-speed Liquid Filling Production Line

(1)Easy to operate, safety and reduce the cost of packing material.

Email Details

(2)Module design, simple structure, short design cycle, higher working capacity.

(3)The packing material can be single material or composite material.

(4)The machine body structure is assembled firm and well-knit.

(5)Higher utilization of packing film which can be more than 95%, some is more than 99%.

(6)The height of bottle can be 60mm to 120mm and filling dose can be 1ml-120ml.

(7) Throughout the cutting device, can divide the plate into single piece or multi pieces connected according to requirement. -

High-speed Sachet Packaging Production Line

(1)Sealing width can be max 600mm, so the machine can do 5 to 10 lanes.

Email Details

(2)The machine use one roll packing film which can be divided two parts for sealing, convenient adjustment.

(3)Lengthways sealing, across sealing, embossing, pertferation knife and finished sachet cutter all were controled by servo motor.

(4)Controlling system: with HMI control and buttone control, this is convinent for the operator to control the machine.

(5)If no packing material,machine will not absorb the carton and leaflet,pusher will stop working.

(6)Machine will stop automatically when ancillary stock in low level.

(7) Machine will stop automatically when there are leaflets but lack of box for three times.

(8)Machine will stop automatically when there are packaged product but lack of leaflets for three times. -

High-speed Blister Packaging Production Line

(1)Adopt full servo control,stable operation,easy adjustment and low noise.

(2)Main parts adopt domestic and international famous brand to ensure the operation smoothly.

(3)The main parts adopt the stainless steel which meet the GMP standard.

(4)For the blister packing machine,there are common feeder,special feeder and so on,it can meet customer’s different requirement.pharmacy blister packing production line food blister packing production line cosmetic blister packing production lineEmail Details