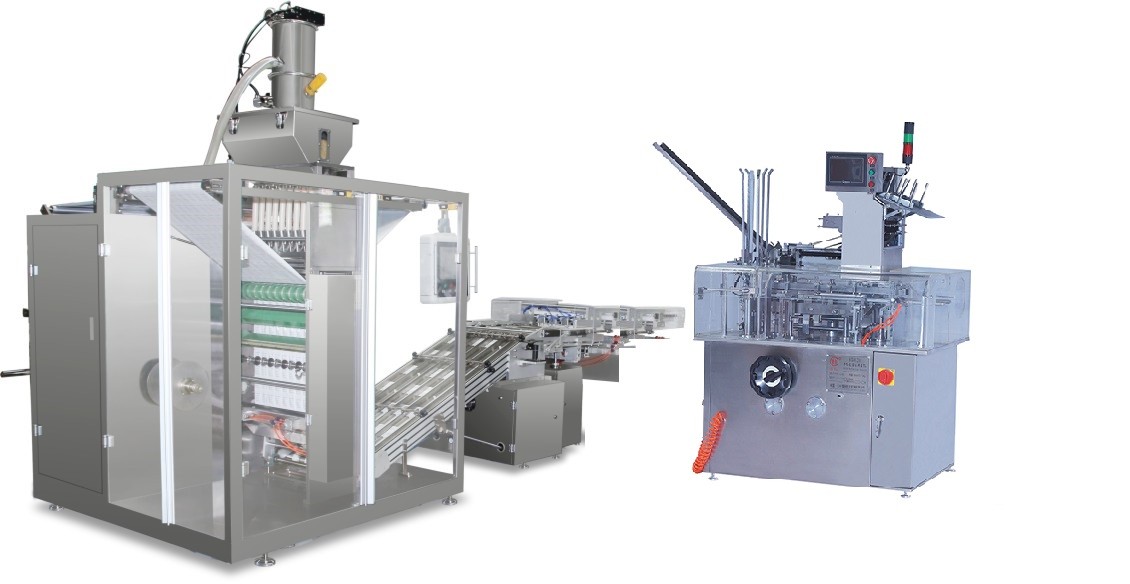

Blister Packaging Production Line

(1)Space of forming,sealing,cutting system can be adjusted freely,suitable for different size plate

(2)Manipulator guiding,adjustable stroke,simple operation,reliability running

(3)Simplicity and convenience of replacing different molds.Changeable frequency

(4)It can be equipped cursor register,servo motor control stroke

(5)If no packing material,machine will not absorb the carton and leaflet,pusher will stop working.

(6)Machine will stop automatically when there are leaflets but lack of box for three times.

(7)Machine will stop automatically when there are packaged product but lack of leaflets for three times.

(8)Emergency stop switch is on electric cabinet,press this button to stop machine instantly when emergency.

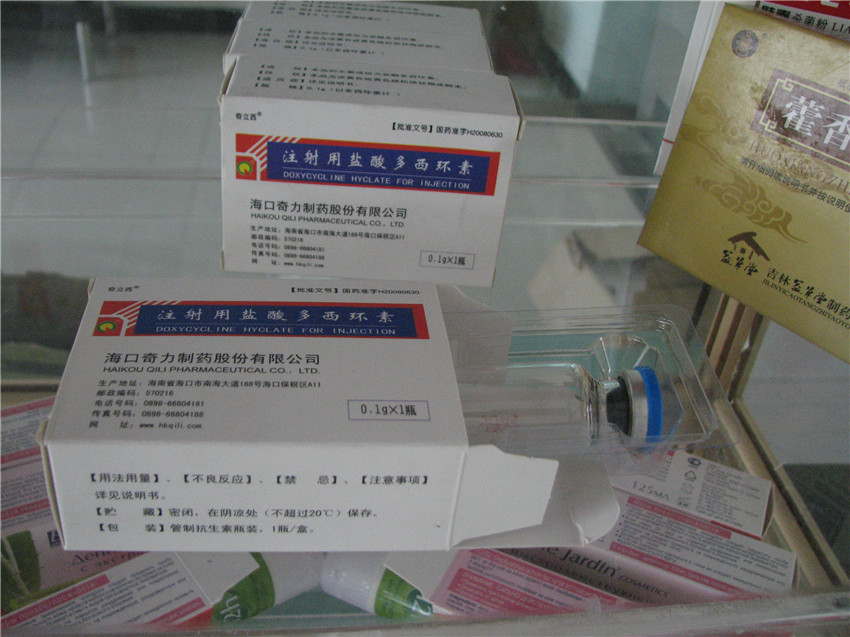

Introduction

This production line composed by plate blister packing machine and automatic carton packing machine,suitable for solid strange shape medicine, ampoule and vial products in pharmaceutical,food,cosmetic and daily use chemical industry.The production form blister,put products into blisters,put blisters into carton.Meet the GMP quality standard,can improve the production capacity,reduce the labor cost,lower the production cost,also can avoid packaging products across.The production line can be OEM according to the customer requirements.

DPP250 Blister Packing Machine

Main technical parameters

1. Packing film

(1)Nontoxic PVC: 0.15~0.50×250mm(Thickness×Width) meet GB5663-8A requirement.

(2)Composite forming:0.14~0.15×250mm(Thickness×Width)

outside roller film diameter ≤Φ400mm

inside roller film diameterΦ70-Φ76mm.

(3)PTP: 0.02×250mm(Thickness×Width)

outside roller film diameter:≤φ280mm

inside roller film diameterΦ70-Φ76mm

2. Cutting times:25~40times/min,4pcs/time

3. Stepping range:60~200mm。

4. Max forming area:160×240mm。

5. Max forming depth:30mm。

6. Total power:6KW

7. Displacement:>0.3m³/min(provide yourself)

Pressure:0.6~0.8MPa

8. Mold cooling:tap water or recycled water consumption:60L/h。

9. Machine size:3600×800×1650mm。(L*W*H)

10. Weight:1650kg

11. Power:220/380V 50Hz

Working principle

PVC hard sheet material is drawn by the open coil mechanism to pull out certain length, supply the next step demand, after heating device, forming device forms bubble cover. After molding, the PVC bubble cover is formed into the intermittent traction of the mechanism, and the continuous working is formed by the continuous bubble belt. The bubble into the feeding part of the platform, the drug by feeding (battery, electric component,bottle etc.) filling in the PVC blister has formed, before the heat sealing and then inhibits PTP aluminum foil to cover in the upper blister, together into the sealing, sealing device for rolling is packaging is placed in the PVC blister and the aluminum foil sealing holes in the nest; This insulates the drug from the atmosphere. And enter the batch number device, according to the preset steel character indentation marks (or broken lines), and then by typing adjusting roller, cutting step into the cutting device packaging semi-finished products of continuous cutting apart, so as to achieve the desired aluminum-plastic blister packaging sector.

HD200 Carton Packing Machine

Main technical parameter

Power supply:AC380V 50HZ Three-phase five-wire system

Max power:1.5kw(single match)

Production capability: host speed: max 200box/min

Folding speed: max 600pages/min

Air consumption:0.06-0.09 m³/min(pressure 0.6-0.9mpa)

Machine dimensions:4800*1620*1600mm(L*W*H)

Weight::About 2500kg

Noise:≤75dB

Normal working condition:

Conditions:25±10℃

Contract air:pressure:0.6—0.9Mpa

Flow:0.6—0.9m3/hour

Operation people:1—2

Working principle

This machine is composed of a series of precision gear transmission, synchronous belt and precision roller chain drive to automatically complete the carton, carton open, drug absorption and folding, instruction for use by transfer of a packaging, boxes, printing production batch number, carton sealing process, etc