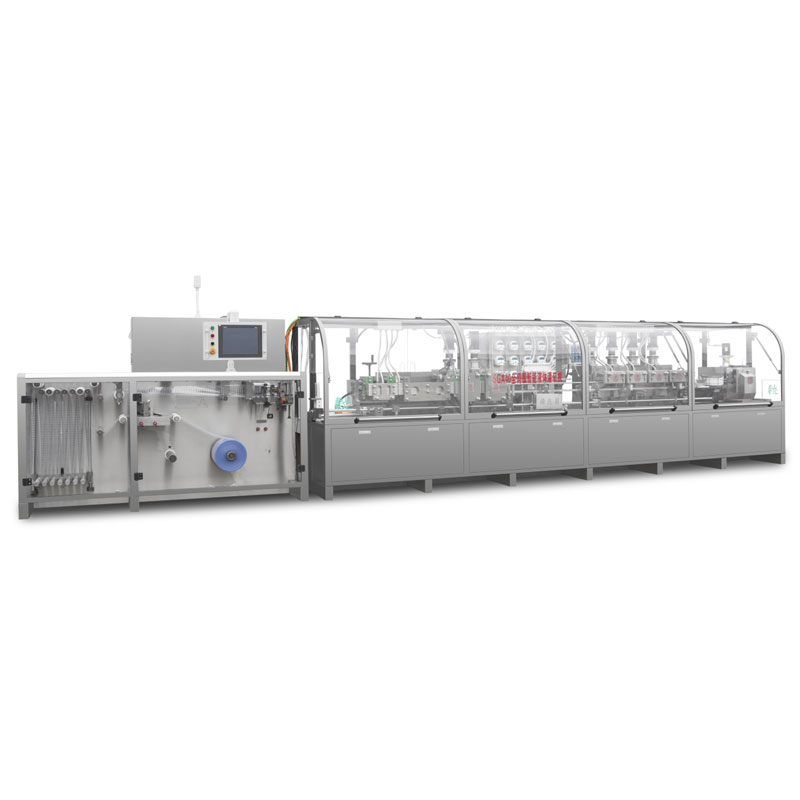

China Pharmaceutical Liquid Filling Packaging Machine Factory Price

(1)Simple structure, safety operation process and reduce the cost of packing film.

(2)Module design, simple structure, short design circle, fast product innovation speed.

(3)Reasonable structure, reliable quality, stable machine running, long machine service life usage.

(4)The packing material can be single material or composite material. PVC(PE), PET(PE), PVDC all can be used as packing film

(5)The machine body structure is assembled firm and well-knit;

(6)Higher utilization of packing film which can be more than 95%, some is more than 99%.

China Pharmaceutical Liquid Filling Machine, Pharmaceutical Packaging Machine Factory, Pharmaceutical Filling Machine Price

Introduction

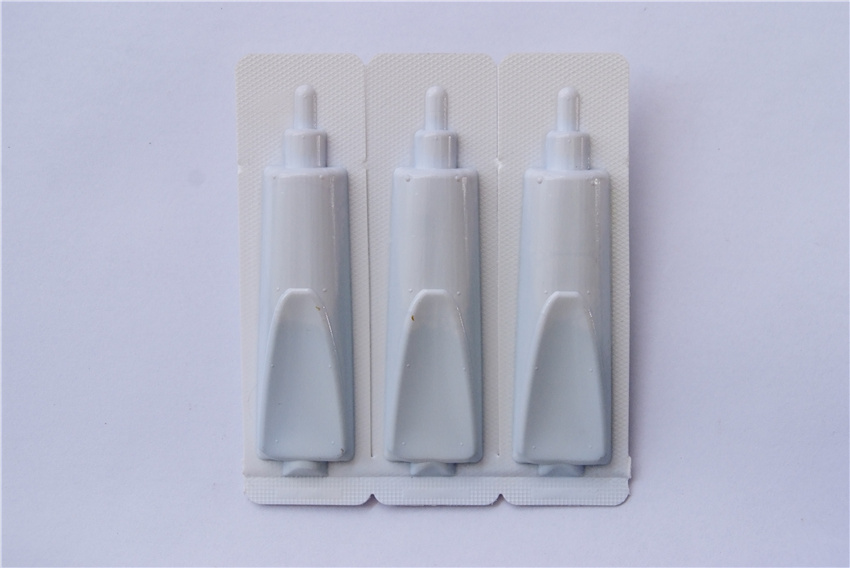

SGA20 automatic liquid packing machine is mainly specialized in dosage packaging of liquid and semi-liquid products. It developed on the basis of many years experiences in this packing equipment industry.

It designed to satisfy the requirement of using plastic rolling film to pack liquid/semi-liquid product.

Application

Pharmaceutical, Food,Cosmetic, Healthy Care Product and Chemical Products etc. The machine can pack product with different shape by changing moulds.

Specification

Packing film: PVC/PE PET/PE composite material

Packing frequency: 100pcs/min (dosage:10ml) 5 nozzles

Packing capacity : 1-60ml

Outer diameter packing film: Φ400m

Inner diameter of packing film: Φ76mm

Power Supply : 380V/50Hz 13KW

Machine dimensions (L×W×H): 2100x1150x1400mm

Machine weight: 1400KG

Working principle

SGA20 liquid packing machine is using plastic ampoule bottle to pack unit dosage liquid or semi-liquid product. To use thermal forming plastic film, it can be folded in half then formed through plastic film folding device. If needed, this machine also can produce flat-bottom plastic ampoule bottle. SGA20 liquid packing machine can finish the process of forming, filling, sealing then the finished product outputted out of the machine after blanking.

Safety protection of the machine

(1)The outer safety protection cover is composed of aluminum, stainless-steel lid and a door with safety switch.

(2)The manual ‘emergency stop’ button is assembled on the surface of machine’s HMI.

Optional choice of safety protection setup

(1)All covers and doors have to close tightly then the machine can be operated;

(2)During machine running process, the machine will be stopped automatically if the door with protection device is opened.

Safety operation rules

1. Only trained machine users can start up the machine in order to maintain safety.

2. Any machine techniques’ changes have to be made by our company’s technicians. Otherwise, our company is not response to any damages that caused by any random changes.

3. Without our authorization, it is forbidden to change or adjust the equipment. Any accident and damage that caused by unauthorized changes, our company is not response to it.

4. The safety protection during production process cannot be ignored. The machine component opening and removing can be happened only during maintenance and fixation operations. And only authorized person can be doing so. This person has to guarantee the operator’s safety during maintenance and fixation stage in order to avoid machine damage.

5. Operator has to wear eye protection glasses, earplug,safety shoes and gloves etc.

6. Before machine maintenance and fixation operations, the power has to be off. Then to press ‘Emergency Stop’ button to avoid unexpected machine start-up.

7. The vacuum system is necessary to be assembled to the toxic gas and vapour emitting products. There is safety system that assembled on the machine, such as protection board and motor transmission network, it needn’t to be removed at the machine running and setup stage. If machine maintaining technicians need, these devices cannot be start-up before the machine is recovered.

8. Warning:Some warning behind the machine such as: warning, careful, attention and so on. Please pay attention to these warning in order to protect machine and operator when operate machine.

9. Find the warning sign on machine. It can warn the damage. For example mark“hot”when heating, mark caution electric on electricity box or link box. Find caution ambition sign on preheating, sealing, and preheating, pre-sealing, sealing of bottle neck. They warn operator may get hurt by the hot surface. Find caution electric sign around electricity box and breaker, they remind operator may get hurt by electric.