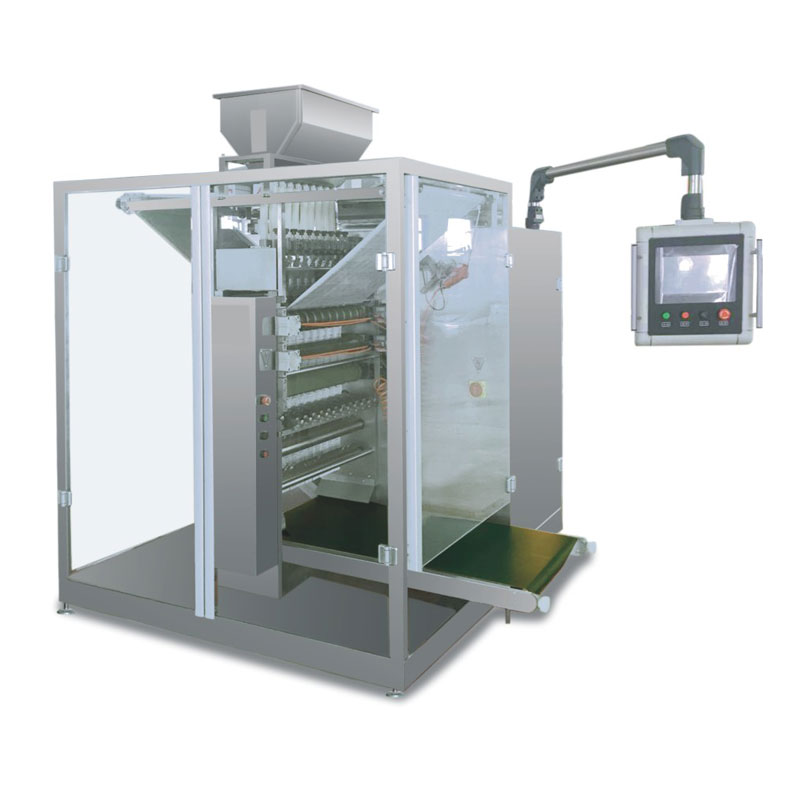

Viscous Liquid Sachet Filling Machine

(1)Sealing width can be max 600mm, so the machine can do 5 to 10 lanes.

(2)The machine uses one roller film which was divided to two pieces in the middle, which bring the convinence for the fast following eye-mark.

(3)Lengthways sealing, across sealing, embossing, pertferation knife and finished sachet cutter all were controled by servo motor.

(4)Lenthways sealing and across sealing, embossing and maine cutter were installation on the machine’s body sides board, which is strong enough to support the machine run continuelly.

(5)The machine structure is compatitive, takes little roomand beautiful desgin.

(6)Electric control pannel: with big room installation.

(7)Controlling system: with HMI control and buttone control, this is convinent for the operator to control the machine.

Introduction

DXDK1200 Sachet Packing Machine with its compact structure is the leadingmachinery in China, which is used to pack pharmaceutical granule, powder and liquid, which is also can be used for food and cosmetic products. The machine meets GMP and CE Standard.

Function

(1)Use servo motor to adjust the sachet’s length.

(2)Controlled by HMI, which run stable and easier to operate.

(3)Servo motor controled photo-sensor to follow the eye-mark which can keep the accurate of the Sachet Mark.

(4)Has the embossing function and easier tearing cutter.

Technical Specifications

1. Pakcing Film: Alu/plastic film, paper/plastic film and so on which can be used for hot sealing film.

Film width:Max 1200mm

Thcikness:0.07-0.1mm

Outside Diameter:≤φ300mm

Inside Diameter:φ70~φ76mm

2. Sealing width:≤550 mm

3. Sachet size:L 50~180 mm ;W 48~150 mm

4. Filling dose:granule:1~50g ;

5. Strokes per minute:50-80times∕M (Up to the filling dose and sachet’s length)

6. Capacity:Max 800 sachets∕M

7. Total power: 13KW

8. Weight: 2000kg

9. Power:380V 、 50Hz

10. Size(L×W×L):2200mm×2000mm×2200 mm

Working theory:

Firstly, the wrapper through the spreading roller unit come to dividing roller unit which the wrapper is cut two parts, then through the dividing roller board and roller into sealing area, enter into lengthways sealing, across sealing, feeding, typing, lengthways cutting, cross-easy cut line ,transverse cutting and finally product from conveyor output.

Equipment installation

1. When swing the machine, make M16 bolt enter into the screw inside the foundation of the machine tool, use steel stick to pry the M16 bolt to uplift the machine, fill up the timber to make the machine leave away the carton. Then use vehicle put up the machine, install the feet screw.

2. Keep enough active space around the device setting up place, this is convenient to operate; the ground should own enough intensity to hold the device.

3. Adjust the device’s level to the condition of working level with the help of the device of tail.

4. Clean the nasty on the surface, you should remember: don’t detach and break the machine, clean all the lubricant area.

5. Check in power、electric pressure and frequency, you should keep them consistent with the device requires, electric pressure:380v, frequency:50hz, keep the power line connecting with changeable on-off behind the electric control box, in the same time ,shut all the automatic on-off in the electrical control.

6. The air pressure of the receive source is 0.6Mpa.

7. Check the operation direction is right or not, make sure the main engine’s rotate direction is not wrong.

Package and transportation of equipment

8. Spread the oil on driving mechanism before shippment,spread the liquid paraffin on the surface.

9. Before the packaging of the equipment the transporter、load material feeder、chute and wrap material roll is unloaded and packaged in addition.

10. In order to avoid the bump in transportation, make sure the lengthways roll、across sealing roll and so on components which are easy bumped are fixed and packed.

11. Use angle iron fixed the equipment and the basement of packaging box.

12. In transportation, the packaging box and the bodywork firmly fixed.

13. If you ship the machine by sea,please make dampproof measure.

Equipment maintain and lubricate

1. Safeguard and maintain

(1)Before the machine runs, the machine must be checked overall, if something is wrong, it must be corrected.

(2)Please inject lube in the lubricated place make it lubricity well.

(3)Everyday, after the production finished, check if sealing roll is stick by the film or not, if it is stick by the package, please keep it clear by the wire brush,but donnot destroy the surface crazing of sealing roller.

(4)The machine must be keep clear, especially the place which easy to touch the stuff of the package, it must be wiped often, so the machine can keep running normally.

(5)The dust on the surface can be clear off by pneumatic gun after production.

2. lubricating

(1)Inject lube in the lubricated place weekly. The lubricated places include: pilot, guiding roll, bearing, bearing sheath and some units which may make relative movement, the lube must be 20or30 machine lube;

(2)The surface of working of the gear, chain wheel, and the chain must be lubricated weekly;

(3)Use the 40# machine lube to lubricate the inside of reducer,changed every half year.