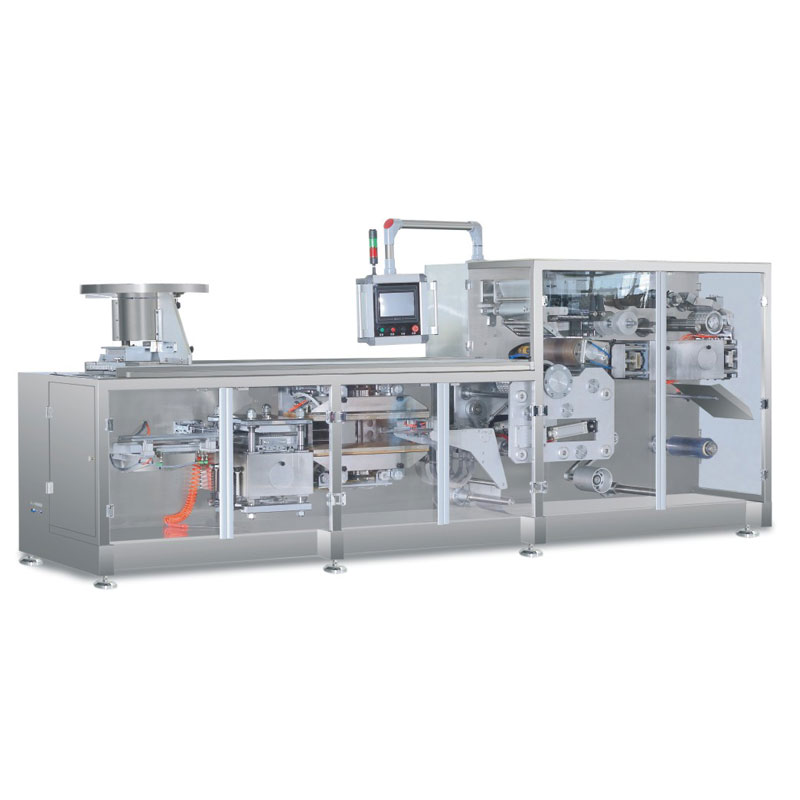

Supplement Blister Packaging Machine

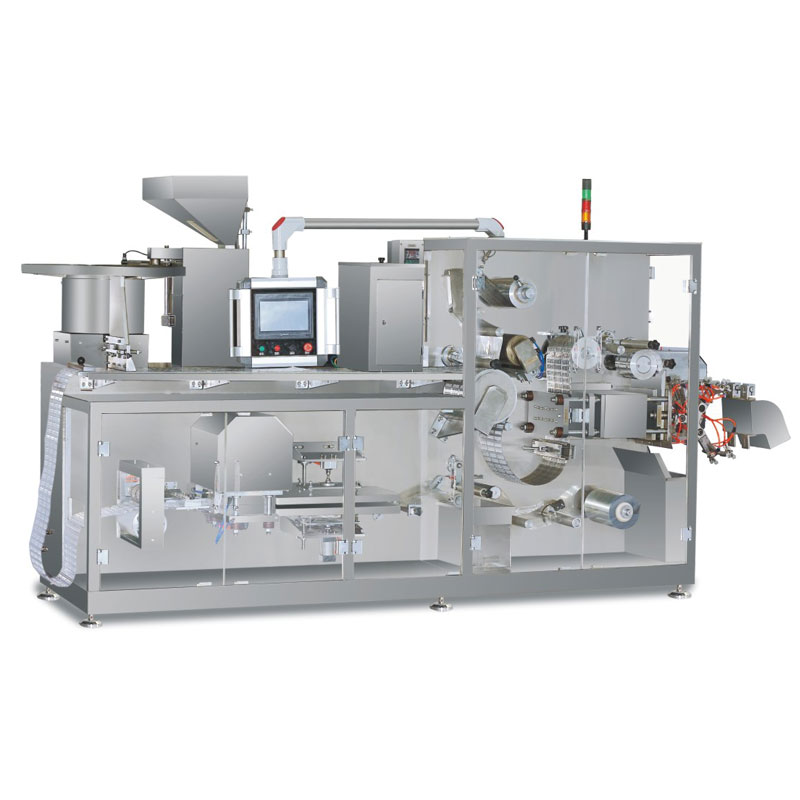

(1)HMI, PLC program control, variable frequency speed adjustment, the speed of strokes less than 200 times per minutes.

(2)Servo step, no synchronization problem, no step distance limitation.

(3)The blanking mold can be in character type, horizontal and longitudinal waste side is small, save the packaging material.

(4)The plate type to form the bubble so the forming area is large, adopt rotary type sealing and the sealing quality is good

(5)Easy to change and adjust the mold.

(6)Noise is below national standards and working conditions complted with GMP Standard.

Introduction

DPH330E Blister packing machine is our company new develop high speed machine which combines the advantage of plate-type and rotary-type machine. With the international high level technology concept,full servo motor,bus control system, modular design,high feeding capacity,intelligent and low noise.Easy operation and mold exchange.Meet GMP quality standard.It is widely used in medicine,health care products,medical devices and electronic components blister packing.

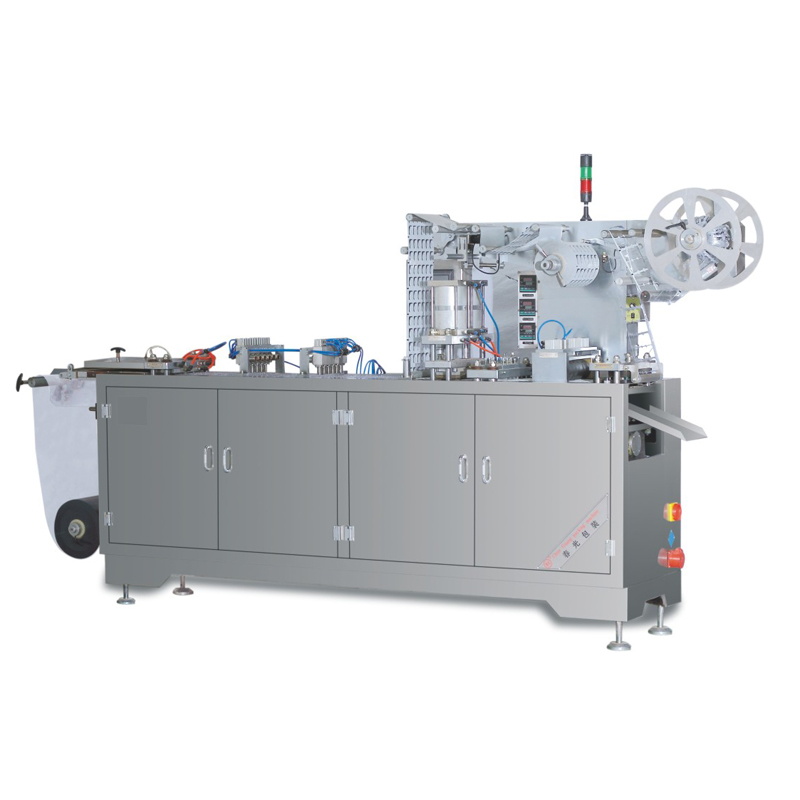

Main technical parameters

1. Largest forming area :260mm×330mm(step distance×PVC width);

2. Deepest forming: 12mm;

3. Packing materials:

(1)PVC:thickness 0.2-0.4mm,max width 330mm,outside roller film diameter≤Φ500mm,inside roller film diameterΦ70-Φ72mm;

(2)PTP: thickness 0.02-0.03mm,same width with PVC ,outside roller film diameter≤Φ250mm,inside roller film diameterΦ70-Φ76mm;

4. Power:380V,50HZ;

5. Total power:20kW;

6. Cooling water pressure:0.1-0.3Mpa,water consumption:0.02-0.05m³/min;

7. Air pressure 0.5-0.6Mpa, air consumption:0.2-0.4 m³/min;

8. Cutting times:≤ 200 times/min(depend on blister size)

9. Machine size:4500×1300×2000mm(L*W*H);

10. Weight:3500kg

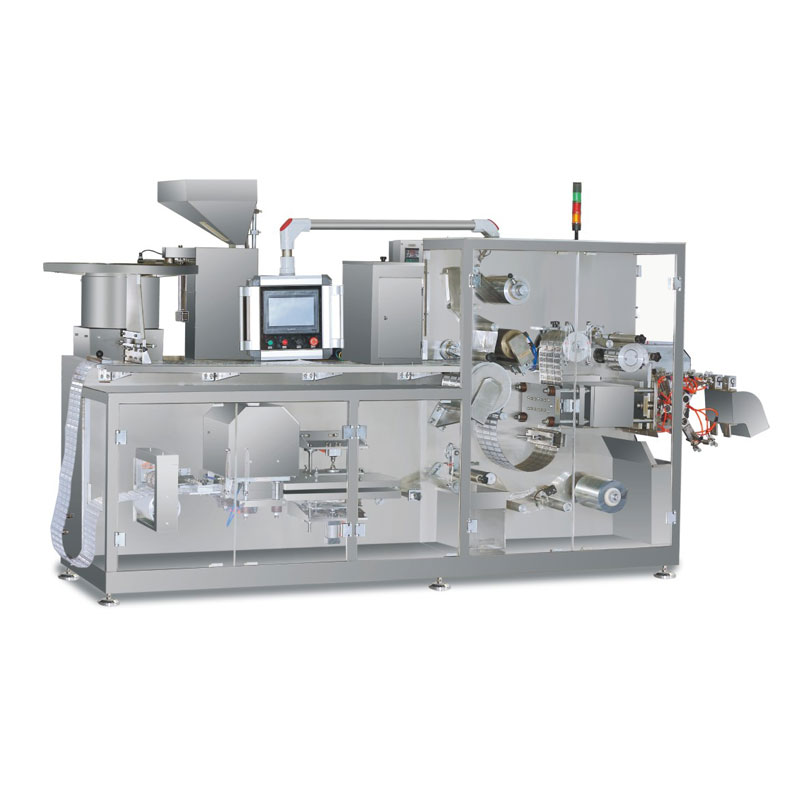

Working principle

PVC hard sheet material is drawn by the open coil mechanism to pull out certain length, supply the next step demand, after heating device, forming device forms bubble cover. After molding, the PVC bubble cover is formed into the intermittent traction of the mechanism, and the continuous working is formed by the continuous bubble belt. The bubble into the feeding part of the platform, the drug by feeding (tablet, capsule, or soft capsule, etc.) filling in the PVC blister has formed, before the heat sealing and then inhibits PTP aluminum foil to cover in the upper blister, together into the sealing, sealing device for rolling is packaging is placed in the PVC blister and the aluminum foil sealing holes in the nest; This insulates the drug from the atmosphere. And enter the batch number device, according to the preset steel character indentation marks (or broken lines), and then by typing adjusting roller, cutting step into the cutting device packaging semi-finished products of continuous cutting apart, so as to achieve the desired aluminum-plastic blister packaging sector.

Packing and moving

1) The machine should be tied up before the box, preventing the falling, and tying up the cylinder before and after the cylinder, so that the piston rod can not be sent out. Foam plastic between the top and bottom heating boards, together, tied up with ropes. Typing, cutting should be in close condition. All rotating parts need to be fixed.

2) Use compressed air to blow the water out of the waterways.

3) The center of gravity is at the center of the big board, and the position and direction should be indicated according to the drawing. When packing, remove the floor foot and use the foot nut to hold the fixed plate (or other fixed plate) together with the box base.

4) Before the case, the relevant documents are packed in a file bag and carried on random. We can also make the plastic shield.

5) The rear of the machine is close to the forklift (figure 16), which should prevent the dumping, collision or turbulence.