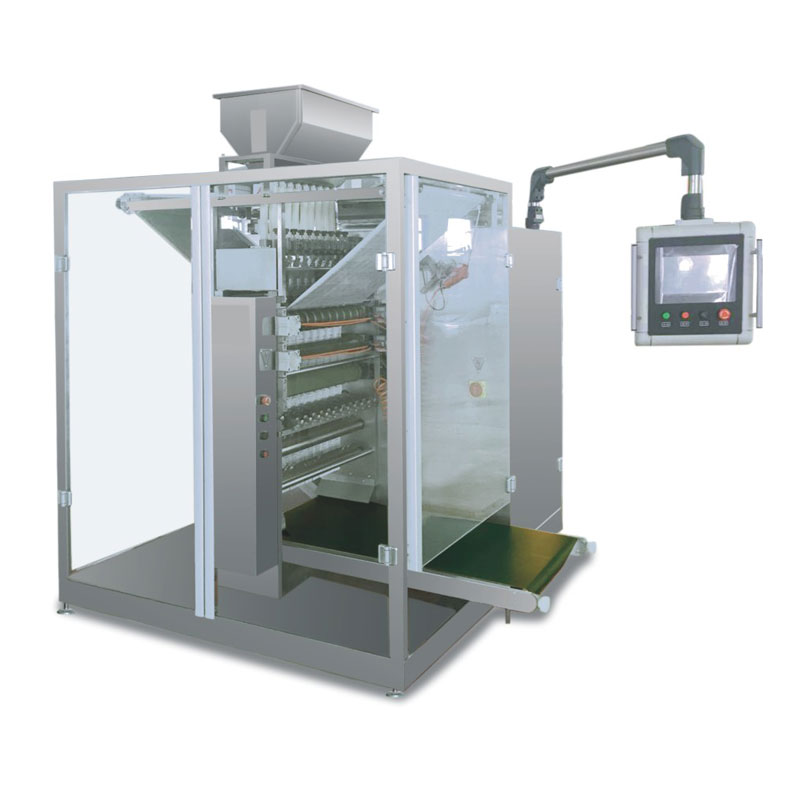

Tablet Sachet Filling Machine

1. Sealing width can be 350mm.

2. Automatic control, stepless speed regulation.

3. Two rolls of packing material heat sealing from two sides to the middle,correct mark automatically and accurately,easy to adjust.

4. Executive mechanisms of sealing, printing, tear-off-lining, cutting, feeding featured in easy adjustment, safe and reliable operation.

5. New structure, diversified configuration meeting client's different requirement.

6. Double side mark tracking can be equipped with detection rejection device.

7. Optical fiber detection device is equipped with dust cover,easy to clear up.

Introduction

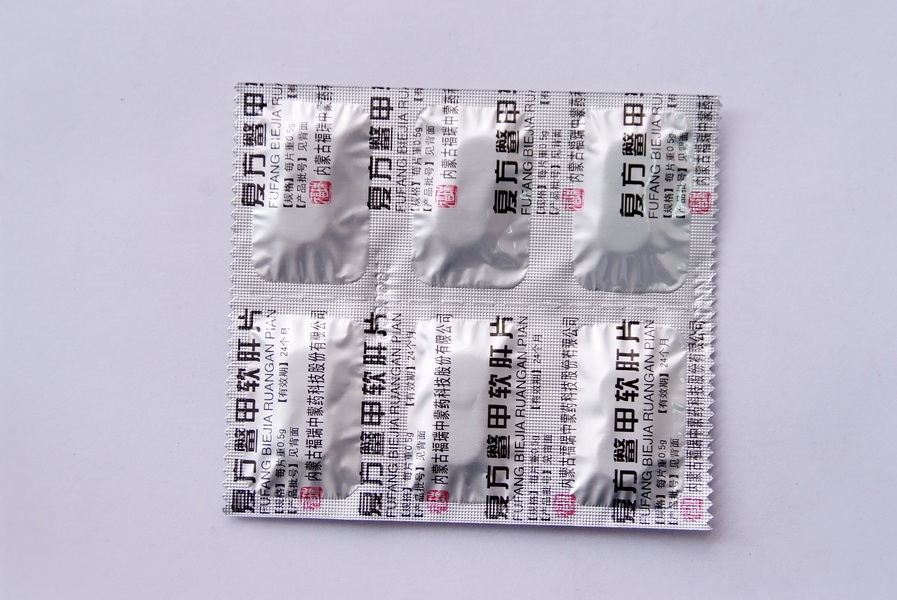

DXDP350 strip sachet packing machine is applicable for tablets, capsules and irregular shapes of pharmaceutical for single or multi pieces packing with lightproof double-Aluminum, which is featured in small size, compact structure, reliable operation, high production efficiency.

Machine is equipped with photoelectric detection,automatic tracking and mark corrected device.Make sure each finished product is good appearance,flat and complete,lightproof,dampproof, long shelf life.Improve product appearance and market competition.

Technical parameter

1. Packing material:Width 350mm

Thickness 0.07~0.1mm

outside roller film diameter≤300mm

inside roller film diameter70~76mm

2. Packing capacity:50~60times/min(Horizontal cutting capacity depend on plate size)

3. Packing film:Plastic-aluminum-plastic composite film

4. Plate size:according to client requirement

5. Total power:5.575KW

6. Power:380V 50Hz

7. Machine dimension(L*W*H):1400×1200×1800mm

8. Weight:1080Kg

Working principle

Drugs are transported to counting disc by dedicated feeder primary vibration.Drived by servo motor,counting disc rotate continuously,(servo motor rotation signal provided by rotary encoder which connect with sealing roller). Feed the tablets through the spring tube and the slide plate into the package material between two mould rollers which is heated with the holes by entary encoder.(as rotate 360°,servo motor rotate once,lead counting disc rotate 20°),With the mould rollers rotation,certain temperature and pressure,seal different kinds of drugs,then emoboss,vertical divided cutting,horizontal divided cutting.Finally transport finished product.

Main structure

Machine mainly consist of following parts:Machine body,transmission system,counting device,sealing,embossing,divided cutting device,waste rejection device,film release device,waste material collecting device,transportation device、PLC electronic control system.

Installation of machine

1. The machine must be securely installed in the designated location,there should be enough space around for easy operation. Adjust the bottom four-point anchor bolt to level the machine.

2. Clear machine surface and each parts,check if the screws and fasteners in various parts are loose.

3. Check if supply voltage and frequency meet equipment requirement.:voltage 380V;frequency 50Hz, power line is connected to the electric control box,each branch switch is off.

4. Pneumatic system require air source pressure should be 0.5~0.6Mpa,connect gas path and check for leaks.

5. Check machine’s running direction.

6. Set the sealing temperature as 110℃-130℃,sealing pressure as 0.3-0.45Mpa.

7. Set preheating temperature of two sieds packing material according to requirement.