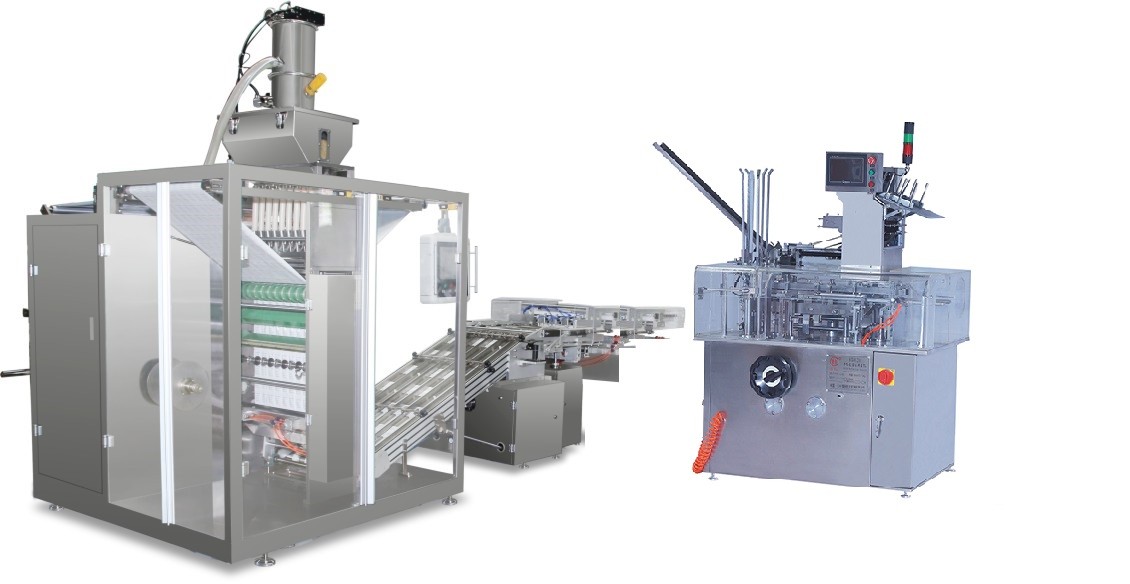

Liquid Filling Production Line

(1)Computer control, stepless speed regulating ,easy for operation

(2)Capability abroad, wildly application, reliable quality

(3)Occupy small area, lower noise, salve the energy sources

(4)Good appearance, new frame, reasonable composition

(5)Changeable shape of bottle, just change the mold, and it is easy job.

(6)Can packing different product and also measure it

(7)PLC program control ,optoelectronic monitoring, stop automatically and display reasons when problem during the working process.

(8)Belt transmission,chain transmission,gear transmission,cam transmission, four bar linkage mechanism and electric and gas control mechanism.

Introduction

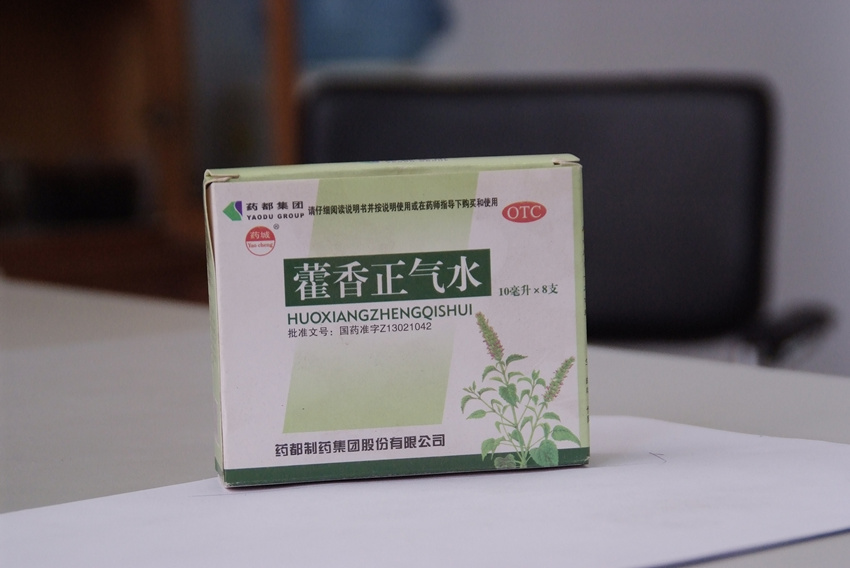

Automatic liquid filling machine and automatic carton packing machine production line is equipped with international high level technology,is the best products in domestic field.The key technology is our patent.This machine adopt two rolls of material to form bottle after heating,then filling pump can immit liquid,semi-liquid and semi-sticky products in exactly dose volume.Finally transport finished product to carton packing machine and insert into carton.The whole process without manual operation,save labor cost,low noise,meet GMP quality standard. The production line can be OEM according to the customer requirements.

DGS350 Liquid Filling Machine

Specification

1、Appearance dimension:4200×1900×1860mm(L*W*H)

2、Weight:3400Kg

3、Voltage:Three phase 380V

4、Power:12kw

5、Cable section area:>6mm²

6、Frequency:50Hz

7、Current(max):15.5A

8、Air compressor power:0.6Mpa/hour, 110L/min

9、Cooling water input size:Φ15mm

10、Cooling water output size: Φ15mm

11、Water consumption:TEMP14-18℃,pressure 0.15--0.2Mpa, shut circle 280L/H

12、Packing material :PVC/PE

(0.3~0.4)*350max(mm)(or depend on the mold )

diameter (max)350mm diameter(inside)70--76mm

13、Number/board:8-15flask/board(according to the volume )

14、Frequency:10-20 board/ml

15、Volume range:1.5-40ml

16、Filling precision:≤3%,according to the national standard

Work principle

This machine can accomplish 21 process from the row material to end product. First heating the packing material and push it to the mold, forming the shape in blowing. And now it is the bottle group, and then cutting them as the single board. Transfer the board to the electronic control program, filling system, sealing, end cutting, batch number, transfer the end product, all above process all transferred manipulator.

The whole process are controlled by program,achieve forming,filling and product output.It is an intelligent production line and the best packing product in pharmaceutical,food and industry.All connected part are made with stainless material which pass GMP standard.

HDS120 Carton Packing Machine

Specification

Power:AC380 50Hz three-phase five-wire

Max power consumption:2.0kW(single match)

Folding speed:Max100page/min

Production capacity:Machine running speed:Max 90box/min

Air consumption:0.2-0.3m3/min(pressure 0.5~0.7MPa)

Machine size:1300×970×1600㎜(L×W×H)

Weight:About 900kg(machine)

Noise:Max 80dB

Working principle

Machine realize carton sucking, carton unfolding, leaflet sucking and folding, material transportation, carton packing, batch lot printing, carton sealing and other process automatically through series of accurate gear transmission, cam transmission and accurate roller chain transmission.